Manual Valvulas Valtek

Valtek Valves The Valtek Valves Sizing & Selection Manual is a comprehensive, easy-to-follow reference guide for determining the proper control valve for a particular application. The material follows the sequential order of the typical Valtek Valves quote sheet. This introduction discusses general information about control valve sizing.

The Valtek ® spring cylinder linear actuator is a powerful. Higher thrust allows tighter valve shutoff. The stiffness of Valtek spring cylinder actuators. Valtek Valdisk Control Valves Valtek No. 49020 GENERAL INFORMATION. If valve is supplied with a lubricator, check lubricant supply and add lubricant if necessary. Valtek Valdisk Control Valves Valtek No. Maintenance on the valve. Valtek actuators with a clamping lever-arm design.

It also outlines the basic control valve parameters which must be known for correct sizing. VALTEK VALVES THE VALTEK FLOWSERVE CONTROL VALVE A Valtek Flowserve Valve is a final control element used in instrumentation systems to regulate the f low, pressure or temperature of liquids and gases in process systems. A control valve is different from other valves in that it has a power positioning actuator for moving the closure mechanism in response to an external signal. The actuator’s energy source is usually provided from an independent source. Section 1: Valtek Mark One Mark One globe-style control valves feature a standard cast carbon steel or stainless steel globe body, top entry trim with a characterized plug contour, high thrust double-acting piston actuator, four-way positioner, and fail-safe return spring. In addition to the carbon and stainless steel construction, Mark One bodies can be furnished in various grades of chrome-moly, alloy 20, Hastelloy “B” and “C”, Monel, Inconel, titanium, bronze, nickel, and other castable materials. The Mark One is available in sizes ranging from 1/2 through 42-inch, and in ANSI Pressure Classes from 150 through 4500.

Body styles include standard globe, globe with expanded outlets (Mark One-X), angle and three-way configurations. A variety of end connections is also available, including raised face, RTJ (ring-type joint), socketweld, buttweld, NPT (National Pipe Threads) and Grayloc. This versatility makes the globe design the most widely used of all control valve types.

Van fictie tot non-fictie. Pragmatica della comunicazione umana ebook. We hebben al duizenden titels voor je verzameld en iedere dag komen daar nog nieuwe verhalen bij. Je vindt alle bekende en minder bekende titels in onze online boekenwinkel. Verhalen in allerlei genres, voor allerlei leeftijden en in diverse talen. Uiteraard vullen we nog steeds graag je boekenplank aan, maar wij van eci adviseren: probeer ook eens een eBook.

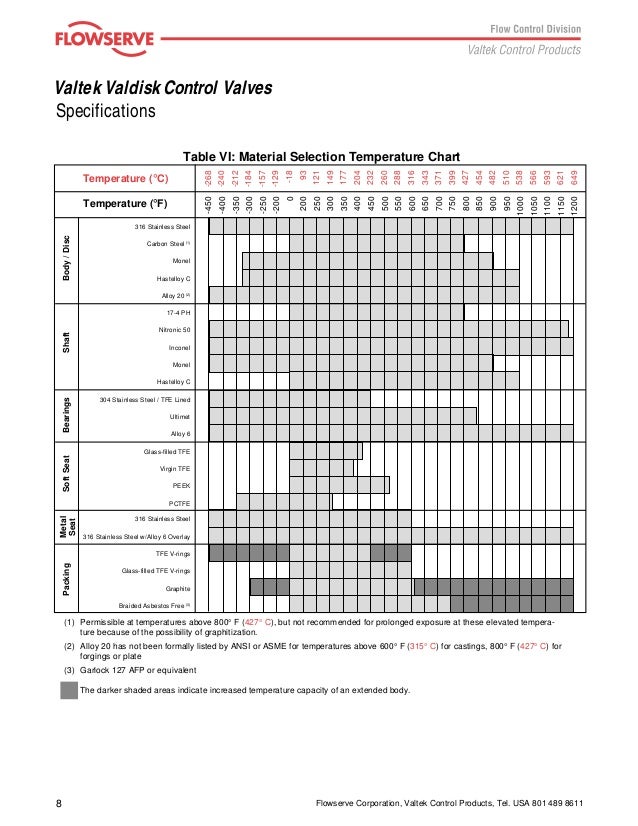

Valtek Mark Two Mark Two control valves are similar to Mark One globe style valves except that the body is fabricated from barstock. It is typically available in sizes from 1/2 through 2-inch and Classes from 150 through 2500. Special designs are also available for body sizes up to 6-inch with special applications to 15,000 psi. Valtek Valdisk Valdisk is a high-performance eccentric disk control valve with quarter-turn action. It utilizes an elastomeric or metal seat for tight shutoff. Valdisk features a flange less wafer body that fits between raised-face line flanges.

Valtek ShearStream ShearStream is a high-performance ball valve designed to overcome the problems of harsh, particle entrained processes. Its high 300 to 1 rangeability, or turn down ratio, also makes ShearStream an ideal control valve for use in high temperature water and steam applications. It is available in sizes 1-inch through 12-inch and ANSI Pressure Classes 150, 300 and 600. Class IV and VI shutoff are achieved with Valtek’s unique FlexLoc TM metal seal and soft seal design, respectively. ShearStream’s V-notch ball design reduces clogging and improves shearing action, making it an ideal control valve for particle entrained processes.The one-piece body design overcomes many long standing challenges faced by traditional ball valves: piping forces that unevenly load the seat, low rangeability due to limited orifice characterization, and unsatisfactory shutoff capabilities. Available body materials include 316 stainless steel and carbon steel. Ball materials available include 317 stainless steel with either hard chrome or Stellite facing.

Valtek MegaStream, ChannelStream and Tiger-Tooth MegaStream, ChannelStream and Tiger-Tooth control valves use special trim enclosed in the standard Mark One body to eliminate problems associated with high pressure drops.MegaStream minimizes the aerodynamic noise associated with gas services. Channel Stream eliminates cavitation and vibration in liquid services.Tiger-Tooth is used in liquid services to eliminate cavitation and in gaseous applications when the required noise attenuation exceeds 20 dB.

All three valves use the same materials of construction as the Mark One. These special trims act to eliminate noise and damaging cavitation which would otherwise severely limit service life of the valve, cause premature mechanical failure of the component parts or prevent personnel from working near the valve. Valtek also offers special service control valves which are designed for a specific application where standard control valves are not particularly suited or easily adapted. Valtek Tek-Check Tek-Check check valves are often used with reciprocating and centrifugal pumps to provide directional flow control.The body and seat ring are both interchangeable with the Mark One.

Tek-Check materials of construction are the same as the Mark One. Valtek Mark Six Mark Six cryogenic valves are specially designed for use in cryogenic air separation columns where all equipment is sealed and insulated in the cold box.Access to the trim is through the valve bonnet.Bodies are available in bronze and various grades of stainless steel. Valtek Mark Eight Mark Eight Y-pattern valves offer a greater capacity per valve size than do standard globe valves, while at the same time retaining the advantages of the globe valve configuration.

Materials of construction are identical to the Mark One. Popular Posts Last 7 days.

What is Flow Compensation? Why do you do process temp. 350 views. 1.Introduction - Installing an Orifice Meter At the en. 148 views. This article is an informal guide with illustrations ai. 63 views.

Any good instrumentation technician needs to know the d. 51 views. Valtek Valves The Valtek Valves Sizing & Selection. 34 views. The primary purpose of a pressure or vacuum r. 32 views. Masoneilan Camflex II The Masoneilan Cam.

Valtek Mark 1

29 views. Masoneilan Level Controllers The Masoneilan 12000 Seri. 25 views. This application note focuses on the idea that orif.